Llantas de carbono vs. llantas de aluminio: La guía comparativa definitiva de 2025

¿Te has preguntado alguna vez por qué los ciclistas profesionales suelen elegir llantas de carbono, mientras que los aficionados prefieren las de aluminio? En el mundo del ciclismo moderno, la elección entre llantas de carbono y de aluminio puede influir significativamente en el rendimiento, la comodidad y el precio. Las ruedas de aluminio ofrecen un rendimiento fiable a un precio asequible, lo que las hace ideales para el ciclismo diario y para ciclistas con presupuesto ajustado. Por otro lado, las llantas de fibra de carbono ofrecen un peso reducido, una aerodinámica mejorada y una capacidad de respuesta superior, ofreciendo una ventaja competitiva en rendimiento, aunque a un precio más elevado. En definitiva, la mejor opción depende de tu estilo de ciclismo, tus objetivos y tus preferencias personales.

En esta sección, comenzamos con el concepto más intuitivo, "peso y aerodinámica", para explicar por qué el peso y la forma de las llantas son cruciales para la eficiencia y el manejo. Ya sea para la eficiencia al subir una cuesta o para la resistencia al viento al esprintar en llano, el peso y la aerodinámica son factores clave.

Al levantar una llanta típica de aluminio de 30 mm de profundidad, se manejan unos 620 gramos de aleación sólida. Si se cambia por una de carbono, se reduce a aproximadamente 420 gramos. ¿Por qué? La aleación de aluminio tiene un peso aproximado de 2,7 g/cm³, mientras que los compuestos de fibra de carbono tienen un promedio de tan solo 1,6 g/cm³.

Las llantas de fibra de carbono permiten a los diseñadores moldear formas complejas y sofisticadas que combinan secciones profundas con una curvatura suave, algo que el estampado de aluminio no puede igualar, optimizando así el flujo de aire alrededor de la rueda. A diferencia de las llantas de aluminio, que requieren un acabado superficial después de la extrusión, la fibra de carbono se puede moldear en el perfil aerodinámico deseado en un solo paso. Imagine una llanta con una sección en U profunda en el borde de fuga, que se estrecha hacia un labio delantero; esta curvatura distribuye suavemente el flujo de aire alrededor de la rueda, mostrando las ventajas únicas del carbono: no solo es ligero, sino también altamente moldeable para un rendimiento aerodinámico superior.

Las cifras pueden ser alarmantes. Con un juego completo de ruedas de carbono, podrías ahorrar 400 gramos en comparación con un juego de ruedas de aluminio, el equivalente a cargar con una botella de agua de medio litro adicional.

Las llantas ligeras responden más rápido. Al salir de una curva, los aros de carbono alcanzan una velocidad en una fracción de segundo que el aluminio no puede igualar.

Tabla comparativa de llantas de carbono y aluminio

|

Característica/Métrica

|

Llantas de carbono

|

Llantas de aluminio

|

|

Peso (llanta de 30 mm)

|

~420 gramos

|

~620 gramos

|

|

Densidad del material

|

1,6 g/cm³

|

2,7 g/cm³

|

|

Aceleración

|

Más rápido

|

Más lento

|

|

Eficiencia de escalada

|

Más alto

|

Moderado

|

|

Modelado aerodinámico

|

Flujo de aire optimizado y altamente moldeable

|

Limitado por extrusión y estampación

|

|

Inercia rotacional

|

Más bajo

|

Más alto

|

Al comparar llantas de carbono con llantas de aluminio, la rigidez y la sensación de conducción son factores cruciales que determinan la eficiencia con la que la potencia de pedaleo se traduce en movimiento. Cada vatio generado se destina a un fin; las ruedas más rígidas transfieren más energía directamente a la propulsión, mientras que las llantas más flexibles absorben parte de esa energía en forma de flexión no deseada.

Cómo afecta la rigidez a la transferencia de potencia

La rigidez mide la resistencia de una rueda a la flexión lateral al levantarse del sillín o al esprintar sobre terreno irregular. Una llanta más rígida permite que una mayor parte del esfuerzo impulse la bicicleta hacia adelante, en lugar de perderse en forma de deformación.

Las llantas de carbono suelen tener una rigidez lateral de entre 70 y 90 Nm/°, mientras que las llantas de aluminio comparables registran entre 45 y 60 Nm/°. Esto significa que las llantas de carbono pueden ser hasta un 50 % más rígidas, lo que proporciona una aceleración más rápida y una transferencia de potencia más eficiente durante los sprints y las subidas.

Respuesta de marcha: Carbono dinámico vs. Aluminio flexible

Las llantas de carbono ofrecen una conducción dinámica: ágil, precisa y optimizada para esfuerzos explosivos. Su alta rigidez proporciona una respuesta instantánea, lo que las hace ideales para corredores y ciclistas agresivos que buscan sentir cada potencia.

Las llantas de aluminio, en cambio, ofrecen una sensación más flexible y tolerante. Su relativa flexibilidad absorbe las vibraciones de los caminos irregulares, mejorando la comodidad durante recorridos largos y reduciendo la fatiga del ciclista. Para los ciclistas de resistencia, esto puede ayudar a mantener una potencia más constante durante periodos prolongados.

Sensación de conducción percibida

Llantas de carbono: Respuesta ultraprecisa, precisión en las curvas y transmisión de potencia inmediata. Preferidas por pilotos que buscan rendimiento y precisión.

Rines de aluminio: Flexión suave bajo carga, absorción de vibraciones y amortiguación en la conducción. Ideales para comodidad, recorridos largos y estabilidad en terrenos difíciles.

Tabla comparativa de rigidez y sensación de conducción

Característica/Métrica

Llantas de carbono

Llantas de aluminio

Rigidez lateral

70–90 Nm/°

45–60 Nm/°

Eficiencia de transferencia de potencia

Alto

Moderado

Respuesta de conducción

Vivaz, ágil, preciso

Flexible, indulgente, cómodo.

Precisión en las curvas

Afilado

Moderado

Absorción de vibraciones

Bajo

Alto

Tipo de jinete ideal

Competitivo / Agresivo

Resistencia / Centrado en la comodidad

Si bien la durabilidad de una rueda afecta tu confianza al montar y su valor a largo plazo, su apariencia influye en cómo te sientes en cada salida. Exploremos el rango de resistencia a la fatiga de las ruedas de fibra de carbono y aluminio y comparemos el atractivo de la apariencia de cada material para diferentes ciclistas.

Al invertir en un juego de ruedas, buscas la confianza de que durará. Las llantas de carbono suelen tener una vida útil de entre 5000 y 8000 kilómetros en condiciones de conducción mixtas. Las capas de carbono de alta calidad resisten las microfisuras, pero los impactos repetidos o un almacenamiento inadecuado pueden acelerar el desgaste. En cambio, las llantas de aluminio suelen resistir entre 10 000 y 20 000 kilómetros antes de que la fatiga se convierta en un problema, casi el doble de la vida útil del carbono.

Un estudio de laboratorio de ruedas de 2024 descubrió que el 85% de las llantas de aluminio mantuvieron la integridad estructural después de 15.000 km, mientras que solo el 60% de las llantas de carbono hicieron lo mismo en pruebas de estrés idénticas.

Las llantas de aluminio, por otro lado, tienen una apariencia más discreta y clásica. Suelen contar con una pista de freno mecanizada y juntas de soldadura visibles, lo que podría no resultar atractivo para quienes buscan una apariencia elegante y futurista. Sin embargo, su simplicidad puede ser atractiva por sí misma, especialmente para quienes prefieren un estilo minimalista o retro.

Las llantas de carbono también ofrecen mayor personalización en cuanto a acabados y gráficos. Desde sutiles tramas hasta llamativas calcomanías, las posibilidades son casi infinitas. Esta flexibilidad te permite combinar tus ruedas con tu cuadro y tu marca personal.

Al comparar llantas de carbono con llantas de aluminio, el precio suele ser un factor clave. Las llantas de fibra de carbono son ligeras y resistentes, pero su producción es compleja y costosa. Cada llanta requiere moldes personalizados, láminas de carbono preimpregnadas colocadas a mano y un curado preciso en autoclave u horno, procesos que exigen mano de obra cualificada e instalaciones limpias y controladas. Los costos de herramientas para perfiles de llanta especializados son elevados, y los menores volúmenes de producción implican que estas inversiones se reparten en menos unidades.

Un estricto control de calidad incrementa aún más los costos. Las llantas de carbono se someten a inspecciones ultrasónicas o de rayos X, pruebas de fatiga e impacto, y un riguroso prototipado para lograr formas aerodinámicas y una disposición optimizada de las fibras. Estos pasos reducen los defectos, pero aumentan los gastos generales de producción y de desarrollo.

Además, el embalaje cuidadoso, el manejo especializado, las certificaciones, la garantía y el posicionamiento premium de la marca contribuyen al precio final. En conjunto, estos factores explican por qué las llantas de carbono son significativamente más caras que las de aluminio, lo que refleja tanto la ingeniería avanzada como las ventajas de alto rendimiento.

Cuidar tus ruedas no se trata solo de mantenerlas limpias, sino también de preservar su rendimiento, seguridad y durabilidad. Ya sea que uses rines de carbono o de aluminio, un mantenimiento adecuado marca una diferencia notable.

En el caso de las llantas de carbono, inspeccione siempre la superficie de frenado o la interfaz del disco después de descensos largos o recorridos en mojado. El calor acumulado por los frenos de llanta puede degradar el carbono con el tiempo, por lo que debe usar pastillas de freno específicas para carbono y evitar frenadas bruscas prolongadas. Limpie las llantas con cuidado con un paño suave y jabón neutro; los productos químicos agresivos pueden dañar el acabado de resina. Busque signos de delaminación o grietas, especialmente alrededor de los orificios de los radios y la pista de frenado.

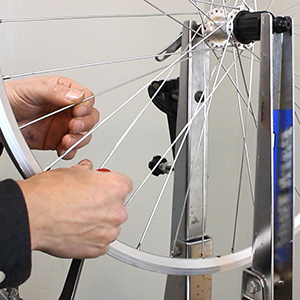

Las llantas de aluminio son un poco más tolerantes, pero aun así requieren atención. Si usa frenos de llanta, revise si hay ranuras de desgaste o superficies irregulares que puedan afectar la potencia de frenado. El aluminio puede oxidarse, por lo que limpiarlo después de usar la bicicleta en zonas húmedas o con sal (como en zonas costeras) ayuda a prevenir la corrosión. Use un cepillo fino o un paño para eliminar la arenilla acumulada cerca de la pista de freno o las cabecillas de los radios.

Ambos tipos de llantas se benefician de un centrado y una revisión de tensión regulares. Una rueda inestable es más que molesta: puede dañar los radios o la propia llanta. Cuida bien tus ruedas y te recompensarán con paseos más suaves y seguros durante años.

Elegir entre llantas de carbono y llantas de aluminio depende de tus prioridades como ciclista: rendimiento vs. valor, velocidad vs. durabilidad, estética vs. practicidad.

Si buscas maximizar cada vatio, escalar montañas o competir contrarreloj, las llantas de carbono son insuperables. Son más ligeras, aerodinámicas y rígidas, lo que se traduce en una mejor transferencia de potencia y una aceleración más rápida. Notarás la diferencia en subidas largas y bajadas rápidas. Además, su elegante diseño le da un toque de estilo a cualquier bicicleta.

Pero el carbono tiene un coste, no solo económico, sino también de fragilidad. Un impacto fuerte o un choque podrían agrietar una llanta de carbono, y las reparaciones pueden ser complicadas o incluso imposibles.

Por otro lado, las llantas de aluminio son muy fiables. Ofrecen mayor resistencia a los impactos, son más económicas de reemplazar y ofrecen un rendimiento constante en todas las condiciones. Si te desplazas al trabajo, montas en gravel o simplemente te inicias en este deporte, el aluminio podría ser la mejor opción.

¿Merece la pena la inversión adicional en llantas de carbono?

Si te interesa el rendimiento o compites, las llantas de carbono pueden valer la pena. Son más ligeras, rígidas y aerodinámicas, lo que se traduce en subidas más rápidas y una conducción más suave. Por ejemplo, unas ruedas de carbono pueden ahorrar hasta 300 gramos en comparación con las de aluminio, suficiente para marcar la diferencia en rutas largas o en competición. Pero si montas de forma casual o con un presupuesto ajustado, el aluminio sigue ofreciendo una excelente relación calidad-precio.

¿Puedo utilizar de forma segura frenos de llanta en ruedas de carbono?

Sí, pero debes usar pastillas de freno específicas para carbono y seguir las instrucciones del fabricante. El carbono se calienta más rápido que el aluminio, especialmente en descensos largos. El sobrecalentamiento puede causar daños o incluso fallos, por lo que es importante frenar a intervalos y evitar el arrastre de los frenos.

¿Con qué frecuencia debo reemplazar mis llantas?

Eso depende de tus hábitos de conducción. Para conductores de alto rendimiento o que se enfrentan a terrenos difíciles, revisa las llantas cada pocos miles de kilómetros. Las llantas de aluminio suelen mostrar desgaste en la pista de frenado, mientras que las de carbono pueden requerir una inspección más detallada para detectar grietas o delaminación.

¿Qué mantenimiento requiere cada material?

El carbono requiere una limpieza suave, cuidado de la pista de frenado e inspecciones regulares. El aluminio es más tolerante, pero también se beneficia de la limpieza, la revisión de la superficie de frenado y el centrado. Ambos necesitan cuidado para durar.

A estas alturas, ya tienes una idea clara de las diferencias entre las llantas de carbono y las de aluminio: el carbono es líder en peso y aerodinámica, mientras que el aluminio gana en precio, facilidad de reparación y gestión térmica. Tu elección ideal depende de tu estilo de conducción, presupuesto y preferencias de mantenimiento. ¿Listo para mejorar tu bici? ¡Explora hoy mismo nuestra cuidada selección de llantas de carbono y aluminio y disfruta del máximo rendimiento!

Categorías

Nuevo blog

Derechos de autor © 2026 Top-Fire Carbon Technology Co., Ltd. Reservados todos los derechos. Poder por

Red IPv6 admitida