Radios de bicicleta: la guía completa

Los radios juegan un papel crucial en el rendimiento, la durabilidad y la calidad general de conducción de cualquier bicicleta. Aunque puedan parecer simples varillas delgadas que conectan el buje a la llanta, los radios son, de hecho, la columna vertebral de la resistencia, la estabilidad y la eficiencia de una rueda. Para los ciclistas que buscan mejoras de alto rendimiento, nuestro Top-fire radios de fibra de carbono proporcionan un diseño ultraligero y una rigidez excepcional, lo que mejora tanto la velocidad como la capacidad de respuesta en la carretera o el sendero

Este artículo explora el polifacético mundo de los radios de bicicleta, desde su función esencial y sus diversos tipos hasta los materiales utilizados en su construcción y los patrones de radiado que determinan la tensión de la rueda. También ofrece consejos prácticos de mantenimiento y orientación para seleccionar los radios adecuados para diferentes disciplinas ciclistas. Para quienes buscan una conducción más suave y reactiva, comprender mejor los radios de bicicleta es un punto de partida ideal.

Los radios son más que una simple conexión entre el buje y la llanta; son vitales para el rendimiento, la comodidad y la durabilidad de una bicicleta. Su impacto se refleja en tres áreas clave.

Una de las funciones más importantes de los radios es distribuir uniformemente el peso del ciclista por toda la rueda. En lugar de concentrar la tensión en un solo punto, los radios distribuyen la carga entre el buje y la llanta. Este soporte equilibrado ayuda a prevenir daños en la llanta y mantiene la rueda fuerte, incluso durante una conducción de alto impacto o cuando se somete a cargas pesadas

La tensión adecuada de los radios es fundamental para la estabilidad de la rueda. Cuando la tensión está equilibrada en todos los radios, la rueda se mantiene recta. Sin embargo, si incluso un radio está demasiado flojo o demasiado apretado, la rueda puede tambalearse, lo que afecta el manejo y la seguridad. Revisar la tensión regularmente ayuda a mantener una conducción suave y predecible

Los radios también ayudan a absorber las vibraciones y los pequeños impactos de la carretera o el sendero. Su capacidad de flexionarse ligeramente bajo presión reduce las fuerzas de impacto sobre el ciclista, lo que mejora la comodidad y reduce la fatiga. Esto es especialmente beneficioso en terrenos accidentados, donde la estabilidad y la tracción son cruciales

La cabeza del radio es el extremo aplanado con forma de hongo que encaja en el buje. Ancla el radio de forma segura en su lugar, lo que le permite transferir el par y la fuerza de rotación del buje a la llanta. Los daños o grietas en la cabeza del radio pueden provocar una falla inmediata y comprometer el rendimiento de la rueda

Ubicado justo al lado de la cabeza, el codo forma un ángulo de 90 grados que permite que el radio salga de la brida del buje y se alinee con la llanta. Esta curva es una zona de alta tensión y es uno de los puntos más comunes donde se produce la rotura de los radios, especialmente si la tensión de los radios es desigual o la rueda está mal construida

El eje es la parte central larga del radio, generalmente fabricado en acero inoxidable para mayor resistencia y resistencia a la corrosión. Las ruedas de alta gama pueden usar radios de doble conificado (más delgados en el centro), de perfil (aerodinámicos) o de fibra de carbono para reducir el peso y la resistencia al viento. El eje debe lograr un equilibrio preciso entre rigidez y flexibilidad para mantener una alineación y absorción de impactos adecuadas.

En el extremo del eje hay una sección roscada que permite que el radio se conecte con la cabecilla. Esta rosca es esencial para ajustar la tensión de los radios, lo que influye directamente en el centrado y la estabilidad estructural de la rueda

La cabecilla es un componente pequeño pero vital que se enrosca en el extremo del radio y se asienta dentro de la llanta. Funciona de forma similar a una tuerca y se puede girar con una llave de radios para ajustar o aflojar la tensión. Un ajuste correcto de la cabecilla garantiza que la rueda se mantenga redonda y equilibrada, lo que permite un rendimiento preciso y una conducción segura.

Los radios con curvatura en J son el tipo más común que encontrarás en las bicicletas. Llamados así por la pequeña curva en forma de "J" cerca de la cabeza del radio, han sido el estándar de la industria durante décadas

Ventajas: Son fáciles de conseguir, económicos y fáciles de reemplazar. Casi cualquier tienda de bicicletas tendrá radios con curvatura en J, lo que permite reparaciones rápidas y económicas.

Desventajas: Esa curvatura es un punto de tensión. Si la tensión de los radios no está bien equilibrada, el codo puede ser más propenso a la fatiga y a romperse con el tiempo.

Aplicaciones típicas: Los radios con curvatura en J se utilizan en todo tipo de bicicletas, desde bicicletas urbanas de nivel básico hasta bicicletas de montaña robustas. Son ideales para ruedas de uso general.

Los radios de tiro recto eliminan la curvatura por completo, ofreciendo una conexión directa y lineal entre el buje y la llanta

Diferencias con J-Bend: Sin ese ángulo de 90 grados, hay menos flexibilidad y menos puntos débiles, lo que le da un radio más fuerte que mantiene la tensión de manera más uniforme.

Ventajas aerodinámicas y de tensión: Estos radios suelen permitir una tensión más alta y equilibrada, lo que mejora la transferencia de potencia y la rigidez de la rueda. Además, al no tener curvas que atrapen el flujo de aire, son ligeramente más aerodinámicos.

Problemas de compatibilidad: Este tipo requiere bujes específicos diseñados para radios de tiro recto. Esto implica menos opciones y, por lo general, un mayor costo de reemplazo.

Los radios de cuchillas, también conocidos como radios aerodinámicos, tienen forma aplanada u ovalada para cortar el viento de manera más eficiente

Reducción de la resistencia al viento: Están diseñados para mejorar la aerodinámica. Al reducir la resistencia, ofrecen una ventaja significativa a los ciclistas de competición, especialmente en contrarreloj o carreras en ruta.

Utilizado en carreras: Las bicicletas de ruta profesionales y las configuraciones de triatlón a menudo dependen de radios con cuchillas, donde cada vatio y segundo cuentan.

Construcción e instalación: Los radios de perfil deben alinearse correctamente durante el montaje de la rueda, de modo que el lado plano quede orientado hacia el viento. Muchos requieren herramientas especiales para su instalación y centrado, lo que los hace menos aptos para principiantes.

Cuando se trata de radios de bicicleta, el material importa mucho. El material adecuado para los radios puede mejorar la resistencia, reducir el peso, mejorar la calidad de la conducción o maximizar el rendimiento aerodinámico

El acero inoxidable es, por mucho, el material de radios más popular en el mundo del ciclismo, y con razón. Es fuerte, duradero y resistente a la corrosión, lo que lo hace ideal para todo, desde bicicletas de paseo hasta ruedas de carretera de alto rendimiento. Los radios de acero inoxidable logran un equilibrio entre fiabilidad y asequibilidad, y mantienen una tensión constante a lo largo del tiempo. La mayoría de los fabricantes de ruedas y mecánicos confían en el acero inoxidable por su historial comprobado y su fácil disponibilidad

Los radios de aluminio son más ligeros que los de acero, pero ese ahorro de peso tiene un coste: son menos duraderos y más propensos a la fatiga y la rotura. El aluminio es más blando, lo que puede provocar deformación o agrietamiento bajo tensión. Por esta razón, los radios de aluminio son poco comunes y se encuentran principalmente en construcciones especializadas o experimentales. Pueden ofrecer ligeras ventajas en cuanto a peso, pero requieren una instalación cuidadosa y no se recomiendan para uso intensivo

El titanio ofrece lo mejor de ambos mundos: más ligero que el acero, pero más resistente que el aluminio, y con una impresionante resistencia a la corrosión. También tiene una cualidad ligeramente elástica que mejora la comodidad de conducción. Sin embargo, este rendimiento superior tiene un precio superior. Los radios de titanio son caros y más difíciles de encontrar, a menudo reservados para construcciones personalizadas o ruedas de alto rendimiento

La fibra de carbono es lo último en tecnología de materiales para radios: ultraligera, increíblemente rígida y diseñada para una máxima eficiencia aerodinámica Radios de carbono se encuentran típicamente en ruedas de carreras de alta gama, donde cada segundo cuenta. No están roscados como los radios de metal; en cambio, están moldeados e integrados en sistemas de buje patentados. Esto hace que sean difíciles de reparar o reemplazar y limita su uso a juegos de ruedas específicos

El número de radios es uno de los aspectos más importantes y más ignorados de una rueda de bicicleta. Influye directamente en la resistencia, el peso y el uso previsto de la rueda. Más radios generalmente significan una mejor distribución de la carga y durabilidad, mientras que menos radios reducen el peso y mejoran la aerodinámica

La mayoría de las bicicletas modernas tienen ruedas de 24, 28, 32 o 36 radios. Cada configuración cumple una función específica:

24 radios: Común en bicicletas de carretera de alta gama y ruedas de competición. Menos radios implican menor resistencia al viento y menor peso, ideal para velocidad y ascensos. Sin embargo, estas ruedas sacrifican algo de resistencia y podrían no ser adecuadas para ciclistas más pesados o terrenos difíciles.

28 radios: Un punto intermedio versátil, habitual en bicicletas de carretera de alto rendimiento. Ofrecen una buena combinación de aerodinámica y durabilidad, lo que las hace ideales tanto para entrenamiento como para competición.

32 radios: El estándar tradicional para muchas bicicletas, incluyendo modelos de cicloturismo y gravel. Estas ruedas ofrecen excelente resistencia y fiabilidad para recorridos de larga distancia o configuraciones de cicloturismo con mucha carga.

36 radios: Diseñados para máxima resistencia. Se encuentran en bicicletas de montaña, tándems y de carga; son ideales para ciclistas que necesitan máxima capacidad de carga y durabilidad.

Bicicletas de carretera: Los radios de 24 a 28 son típicos para un rendimiento ligero. Los ciclistas de competición suelen elegir 24 para velocidad, mientras que los ciclistas de resistencia pueden optar por 28 para mayor soporte.

Bicicletas de grava y ciclocross: de 28 a 32 radios ofrecen la durabilidad necesaria para terrenos mixtos sin agregar peso excesivo.

Bicicletas de montaña: Generalmente de 32 o 36 radios, según el estilo de conducción. Los ciclistas de descenso o enduro más agresivos suelen preferir 36 radios para una máxima resistencia al impacto.

Bicicletas de paseo y de carga: Opte siempre por bicicletas de 36 radios. Al transportar equipo o pasajeros, la resistencia estructural es fundamental.

Bicicletas eléctricas (E-bikes): normalmente tienen 36 o más radios para soportar el peso adicional del motor y el sistema de batería.

La forma en que se disponen los radios, conocida como patrón de entrelazado, afecta en gran medida la resistencia, la capacidad de respuesta y la durabilidad de una rueda. El entrelazado no es solo una cuestión de estética; se trata de física, tensión y función

El entrelazado radial es el patrón de radios más directo y minimalista. En este diseño, los radios van directamente desde el buje hasta la llanta sin cruzarse con ningún otro radio

Ligero y aerodinámico: Gracias a que el radiado radial utiliza radios de la menor longitud posible, reduce el peso y ofrece menor resistencia al viento. Esto lo convierte en el favorito para ruedas delanteras de alto rendimiento en bicicletas de carretera.

Ideal para ruedas delanteras sin frenos de disco: El radio radial no está diseñado para soportar un par elevado. Por eso se usa casi exclusivamente en ruedas delanteras sin frenos de disco. En ruedas traseras o con freno de disco, la falta de radios cruzados puede provocar que se salgan por tensión.

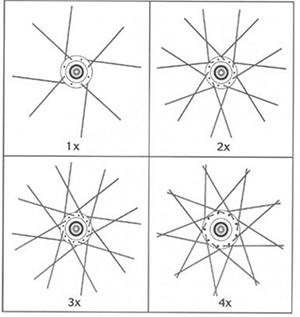

Estos patrones se refieren a cuántas veces cada radio se cruza con otros radios del mismo lado del buje. Cuantos más cruces haya, más largo será el radio y más fuerza podrá soportar

2-Cross (2X): Cada radio se cruza con otros dos. Este patrón ofrece un equilibrio entre ligereza y resistencia. Se suele usar en ruedas ligeras que necesitan soportar algo de par, como en ciclocross o gravel.

3-Cross (3X): El patrón más común en bicicletas de carretera, gravel y montaña. Cada radio se cruza con otros tres, lo que proporciona una excelente resistencia, tensión uniforme y absorción de impactos. Es la opción ideal para una mayor durabilidad sin un peso excesivo.

4-Cross (4X): Se utiliza principalmente en aplicaciones de alto rendimiento, como bicicletas tándem, de carga o de descenso. La mayor distancia entre radios y los múltiples cruces hacen que la rueda sea más robusta, pero añaden peso y complejidad.

Ciclistas de carretera: radial (delantera) y 2X o 3X (trasera) para una combinación de velocidad y confiabilidad.

Gravel y ciclocross: 3X para un equilibrio entre fuerza y capacidad de respuesta.

Ciclistas de montaña: 3X o 4X, dependiendo de qué tan agresivo sea el terreno y el estilo de conducción.

Turismo y carga: siempre 3X o 4X para garantizar la máxima capacidad de carga.

Seleccionar los radios correctos no es solo una cuestión de la estética de la rueda: es una decisión crucial que influye en el rendimiento, la durabilidad y la seguridad de la bicicleta.

Estilo de conducción: Los ciclistas más agresivos que esprintan, suben cuestas o se enfrentan a terrenos difíciles requieren radios más resistentes y duraderos, a menudo con mayor número de radios y un entrelazado más robusto. Los ciclistas ocasionales o aficionados pueden priorizar el ahorro de peso y la aerodinámica.

Tipo de bicicleta: Cada tipo de bicicleta tiene exigencias únicas:

Las bicicletas de carretera se benefician de ruedas ligeras con pocos radios (a menudo de 24 a 28) para mayor velocidad y eficiencia. Los ciclistas que buscan el máximo rendimiento pueden considerar las ruedas Top-fire. radios de carbono para mejorar la aerodinámica y reducir el peso.

Las bicicletas de montaña requieren entre 32 y 36 radios para soportar golpes, impactos y condiciones difíciles

Las bicicletas de grava se ubican en el medio, generalmente con 28 a 32 radios para lograr rendimiento y durabilidad.

Las bicicletas eléctricas ejercen una presión adicional sobre las ruedas debido a la potencia motorizada y al peso adicional, lo que hace que 36 radios o más sean ideales.

Peso del ciclista: los ciclistas más pesados necesitan ruedas con más radios y materiales más resistentes para evitar la fatiga de los radios y la flexión de las ruedas.

Terreno: Los caminos difíciles, senderos o rutas con mucha carga requieren ruedas robustas y resistentes a los impactos. En estos casos, los radios de acero inoxidable con radios de 3 cruces son una opción fiable.

Existe una correlación directa entre el número de radios y la resistencia de la rueda. Un mayor número de radios implica una mejor distribución de la carga y mayor durabilidad, pero a costa de un mayor peso y una ligera mayor resistencia aerodinámica. Un menor número de radios reduce el peso y mejora la velocidad, pero sacrifica la resiliencia y puede ser más propenso a fallar bajo tensión.

La rotura de radios suele ser el resultado de una combinación de factores en lugar de un solo defecto. Las causas más comunes incluyen:

1. Fatiga del metal por años de uso o tensión inadecuada.

2. Corrosión, especialmente en radios de menor calidad o en ambientes húmedos y salados.

3. Mala construcción de las ruedas, como tensión desigual de los radios o patrones de encordado desalineados.

4. Daños por impacto causados por baches, saltos o choques.

1. La fatiga de los radios no se produce de la noche a la mañana. Hay señales sutiles que los ciclistas pueden detectar:

2. Un sonido de "tintineo" al andar puede indicar que un radio se rompe o se mueve bajo tensión.

3. El tambaleo de las ruedas o el roce contra las pastillas de freno pueden indicar una tensión desigual o un radio roto.

4. Grietas visibles o corrosión cerca de la cabeza del radio o del área del niple.

La inspección periódica y los controles de tensión, especialmente después de viajes largos o impactos, pueden prevenir problemas mayores en el futuro.

1. La inspección regular es el primer paso para prevenir problemas en los radios. Los expertos recomiendan revisar la tensión de los radios al menos una vez al mes, o con mayor frecuencia para ciclistas de todoterreno, de paseo o de bicicletas eléctricas

2. Gire la rueda y busque vibraciones de lado a lado, que pueden indicar una tensión desigual en los radios.

3. Aprieta los pares de radios con los dedos. Todos deben tener la misma firmeza; si alguno está mucho más suelto, podría necesitar atención.

4. Escucha: Los radios sanos emiten un sonido claro al pulsarlos. Un sonido apagado o plano puede indicar pérdida de tensión o fatiga.

1. Se pueden hacer pequeños ajustes con una llave de radios. Apriete o afloje ligeramente la boquilla para restablecer el equilibrio, pero siempre en incrementos pequeños.

2. En caso de desalineación más grave, o si varios radios están afectados, lo mejor es acudir a un rinero profesional. Una tensión incorrecta puede causar más problemas que beneficios.

1. Utilice un cepillo suave o un paño con agua tibia y jabón para limpiar alrededor de los radios y las cabecillas.

2. Evite el uso de desengrasantes o disolventes agresivos, ya que pueden dañar los recubrimientos protectores.

3. Enjuague bien y seque con un paño limpio.

Los radios de la bicicleta son más que simples componentes de las ruedas: son los compañeros silenciosos en cada recorrido, ya sea que estés recorriendo senderos o persiguiendo la velocidad. Comprender los tipos de radios, los materiales, la tensión y los patrones te ayuda a sacar el máximo provecho de tus ruedas. El mantenimiento regular y las actualizaciones bien pensadas pueden contribuir en gran medida a mejorar la calidad y la seguridad de la conducción

1. ¿Con qué frecuencia debo revisar la tensión de los radios de mi bicicleta?

Al menos una vez al mes, especialmente si montas con frecuencia o en terrenos difíciles

2. ¿Puedo montar en bicicleta con un radio roto?

No es ideal, pero puedes recorrer distancias cortas con cuidado. Repáralo cuanto antes para evitar dañar la llanta.

3. ¿Es siempre mejor tener más radios para mayor resistencia?

No siempre. Más radios = más peso. Depende de tu estilo de conducción y del terreno.

4. ¿Cuál es el mejor material de radios para ciclismo de montaña?

El acero inoxidable es la opción preferida por su durabilidad y absorción de impactos.

5. ¿Centrar las ruedas es lo mismo que ajustar la tensión de los radios?

Están estrechamente relacionados. El centrado implica apretar o aflojar los radios para enderezar la rueda.

Categorías

Nuevo blog

Derechos de autor © 2026 Top-Fire Carbon Technology Co., Ltd. Reservados todos los derechos. Poder por

Red IPv6 admitida