Llantas de carbono para carretera vs. llantas de aleación: ¿cuáles deberían recomendar las tiendas de bicicletas en 2025?

En esta guía, le explicaremos las diferencias clave entre Llantas de carretera de carbono y aleación. Al final, sabrás qué recomendar con seguridad a tus clientes en 2025, ayudándolos a conducir mejor.

Cuáles son

Llantas de carretera de carbono

?

Carbón

llantas de carretera

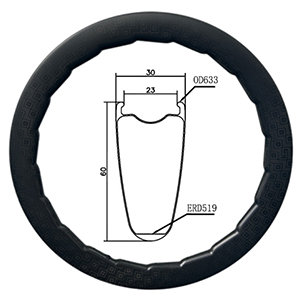

Son llantas de bicicleta fabricadas principalmente con fibra de carbono, que se dividen en materiales de grado Toray T700/T800, reconocidos por su extrema ligereza y resistencia. Estas llantas ofrecen mayor rigidez y capacidad de respuesta en comparación con las llantas de aleación tradicionales, lo que ayuda a los ciclistas a acelerar más rápido, subir cuestas con mayor facilidad y disfrutar de una conducción más suave.

Cuáles son

Llantas de aleación para carretera

?

Las llantas de aleación para carretera son ruedas de bicicleta fabricadas con metales como el aluminio. Son ampliamente utilizadas por su durabilidad, precio y fiabilidad para diversos tipos de ciclismo. Si bien no son tan ligeras como las llantas de carbono, las llantas de aleación ofrecen un rendimiento sólido y soportan el desgaste diario sin mayores inconvenientes.

Materiales, tipos de tejido y fabricación de llantas de carbono

Comprender los aspectos técnicos de las llantas de carbono para carretera puede ayudarte a recomendar los productos adecuados a tus clientes. El material, el tipo de tejido y el proceso de fabricación influyen en el rendimiento, el peso y la durabilidad.

Materiales de fibra de carbono

La mayoría de las llantas de carretera de carbono de alta calidad están hechas de fibra de carbono unidireccional (UD) o tejida. Fibra UD alineada

Las fibras de carbono se entrelazan en una sola dirección, lo que hace que las llantas sean más ligeras y rígidas. Las fibras tejidas, como las de 3K o 12K, se entrecruzan, lo que aumenta la resistencia y la resistencia al impacto. Conocer la diferencia ayuda a comprender por qué algunas llantas rinden mejor en subidas o curvas.

Llantas de carbono para carretera vs. llantas de aleación

|

Característica

|

Llantas de carretera de carbono

|

Llantas de aleación para carretera

|

Qué significa para sus clientes |

|

Peso

|

Muy ligero, ayuda en subidas y aceleración.

|

Más pesado, añade estabilidad pero requiere más esfuerzo para subirlo.

|

Las llantas ligeras son ideales para corredores o ciclistas de larga distancia; las llantas de aleación son adecuadas para paseos ocasionales.

|

|

Rigidez

|

Alta rigidez, manejo sensible.

|

Rigidez moderada, ligeramente menos sensible.

|

Las llantas de carbono brindan a los ciclistas una sensación más directa; las llantas de aleación brindan una conducción más suave y tolerante.

|

|

Durabilidad

|

Fuerte pero sensible a impactos o choques.

|

Muy duradero y resistente a los impactos.

|

Los clientes que priorizan la longevidad o el uso en carreteras difíciles pueden preferir llantas de aleación.

|

|

Aerodinámica

|

Mejor flujo de aire, especialmente en diseños de secciones profundas

|

Ventaja aerodinámica limitada

|

Las llantas de carbono ayudan a los corredores y ciclistas orientados al rendimiento a reducir la resistencia.

|

|

Precio

|

Costo inicial más alto

|

Más asequible

|

Las llantas de aleación son rentables; las llantas de carbono ofrecen beneficios de rendimiento que valen la inversión para los ciclistas serios.

|

|

Mantenimiento

|

Requiere un manejo cuidadoso; reparaciones más complejas.

|

Fácil de mantener y reparar.

|

Las llantas de aleación son adecuadas para los clientes que desean opciones de bajo mantenimiento.

|

|

Comodidad de conducción

|

Conducción más rígida, menor absorción de vibraciones.

|

Conducción más indulgente, absorbe pequeños baches.

|

Los ciclistas que se centran en la comodidad pueden disfrutar de la aleación; los ciclistas de alto rendimiento se inclinan por el carbono.

|

¿Por qué deberías?

Recomendar

Llantas de carretera de carbono

en 2025

Reunión Creciendo

do

usto

mer

Demanda

Las llantas de carbono para carretera son cada vez más populares entre los ciclistas. Buscan ruedas más ligeras, rápidas y con mayor capacidad de respuesta. Al ofrecer opciones de carbono, puedes satisfacer las expectativas tanto de ciclistas de competición como de aficionados entusiastas.

Beneficios de rendimiento

para

o

Ciclistas

Peso más ligero:

Subida más fácil y aceleración más rápida.

Recomendar llantas de carretera de carbono también puede ayudar a su negocio:

Cómo ayudar a los clientes

Elige las llantas de carbono para carretera adecuadas

Antes de recomendar llantas de carbono para carretera a tus clientes, es importante entender cómo adaptar cada llanta a sus necesidades específicas. No todos los ciclistas se benefician del mismo tipo de llanta, y conocer las diferencias te ayudará a ofrecer consejos realmente útiles.

Coincida con el tipo de llanta

Ridi

ng

Estilo

No todas las llantas de carbono para carretera son iguales. Al atender a los clientes, pregúntales sobre sus hábitos ciclistas:

Las llantas de carbono varían desde opciones básicas hasta las de gama alta. Analicemos las ventajas y desventajas:

Marca

y

T

desgarra

y perspectivas futuras para las llantas de carbono para carretera

Después de ayudar a sus clientes a elegir las llantas de carbono de carretera adecuadas, es útil comprender la evolución del mercado. Las tendencias en tecnología ciclista y las preferencias de los ciclistas pueden influir en las llantas que ofrece y recomienda.

Creciente popularidad de

Auto

bueno

Llantas

La demanda de llantas de carbono para carretera está en aumento a nivel mundial. Cada vez más ciclistas, desde aficionados hasta profesionales, buscan ruedas ligeras y de alto rendimiento. Esta tendencia demuestra que las tiendas de bicicletas que ofrecen llantas de carbono probablemente verán un creciente interés por parte de los clientes.

Tendencias clave

i

norte

2025

Diseños tubeless-ready: los ciclistas prefieren llantas que puedan utilizar neumáticos sin cámara para un mejor agarre y comodidad.

Concentración

ilusión

Ayudar a sus clientes a elegir las llantas de carretera adecuadas empieza por comprender las diferencias entre las opciones de carbono y aleación. Las llantas de carretera de carbono ofrecen un rendimiento ligero, mayor rigidez y mejor aerodinámica, ideales para ciclistas que buscan velocidad, eficiencia y capacidad de respuesta. Las llantas de aleación, por otro lado, son duraderas, fiables y económicas, lo que las convierte en una opción práctica para el ciclista diario.

Como propietario de una tienda de bicicletas, conocer los materiales, los procesos de fabricación y las tendencias del mercado te da una ventaja. Puedes recomendar con confianza llantas que se ajusten a los objetivos y preferencias de cada ciclista, a la vez que te mantienes a la vanguardia de la competencia.

Al combinar tus conocimientos técnicos con la comprensión de las necesidades de los clientes, ayudas a los ciclistas a disfrutar de una mejor experiencia ciclista y consolidas la reputación de tu tienda como proveedor confiable de ruedas de alta calidad. El inventario y la promoción de llantas de carbono para carretera en 2025 no solo satisfacen la creciente demanda, sino que también abren oportunidades para aumentar las ventas y fortalecer la fidelidad de los clientes.

Categorías

Nuevo blog

Derechos de autor © 2026 Top-Fire Carbon Technology Co., Ltd. Reservados todos los derechos. Poder por

Red IPv6 admitida